Future of robots, on the line

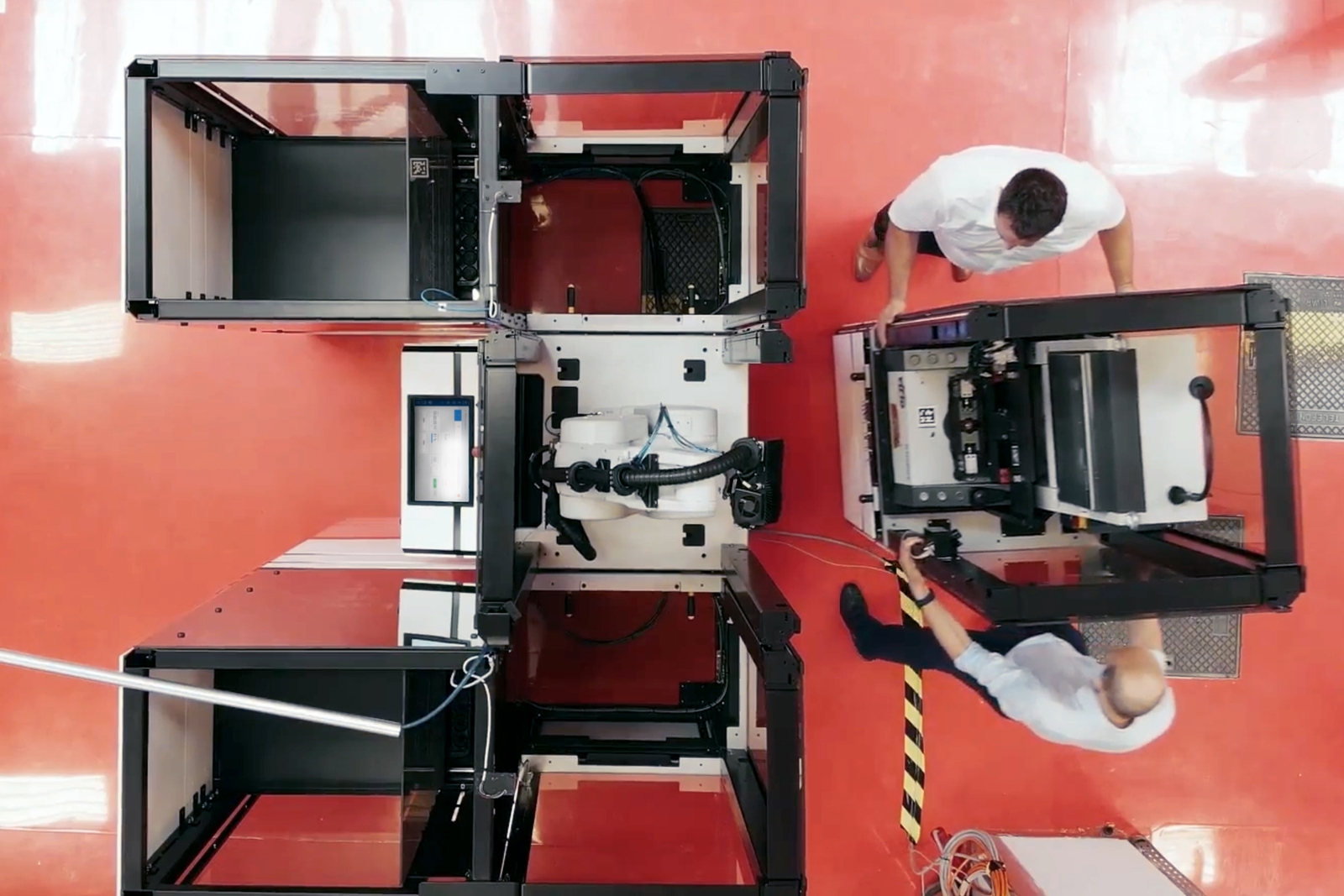

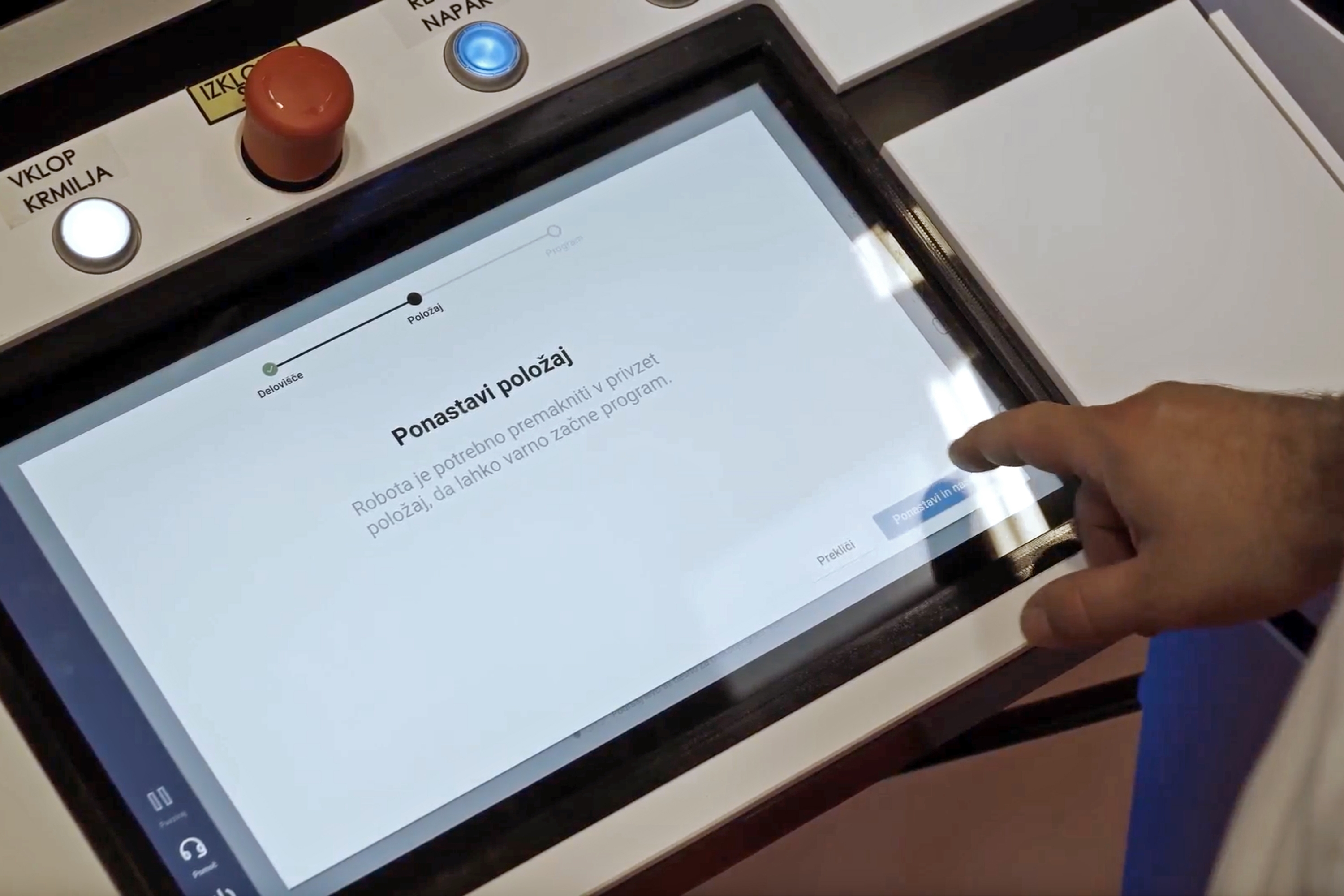

Setting up the robot's workstation. photo_camera by Kolektor Digital

How the Slovene manufacturing company built a collaborative robotic fleet for the international market, amid a global pandemic and a precarious business climate.

By humanising automation

Helping factory workers interact with robots in an accessible, friendly way has been paramount to their productive relationship.

By employing co-creation

Have we not had access to factory staff from the kick-off onward, product development would take much longer, with more setbacks.

By embracing limitations

Manufacturing facilities are highly regulated. We made the remote access to robots possible, by figuring out how factory staff can supervises it.

By adressing all stakeholders

Factory workers' UX (user experience) was not our only concern. We also improved the DX (developer experience) for those deploying the robots.

By going geyond R&D

We helped Kolektor Digital adopt new practices while accommodating existing tools and workflows in their robotics department.

By excellent teamwork

Our remote-friendly Ways of Working made sure the Coronavirus pandemic, or the team’s geographical distribution, did not bring the initiative to a halt.

The whole story

Local collaboration, global impact

A fleet of human-scale, intelligent robotic workers could solve many challenges manufacturing companies are exposed to every day, such as lack of workforce, need for increased production flexibility, continuous improvement of product quality, and reducing manufacturing costs. It’s one of the key “smart” solutions that Kolektor seeks to offer in the global market to transform efficiency, flexibility, and quality of manufacturing. 3fs dedicated a team to embed with their R&D arm, Kolektor Digital, to build the robots’ cloud platform and digital apps.

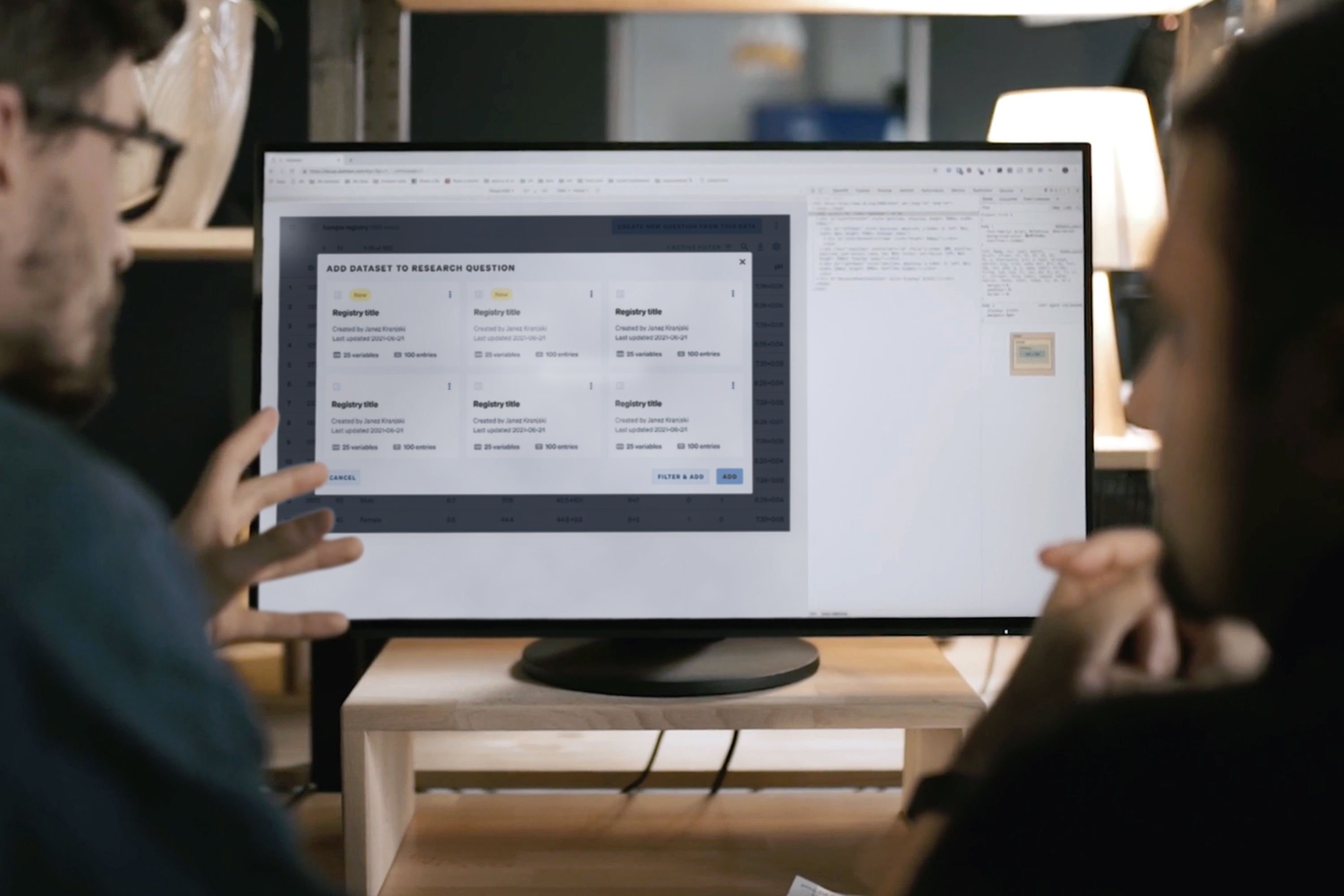

Our kick-off workshop included Kolektor's R&D staff and factory representatives, generating a lot of valuable insights.

Detailed demos of robot usage on the factory floor made it easier to understand its role and operations. photo_camera by Kolektor Digital

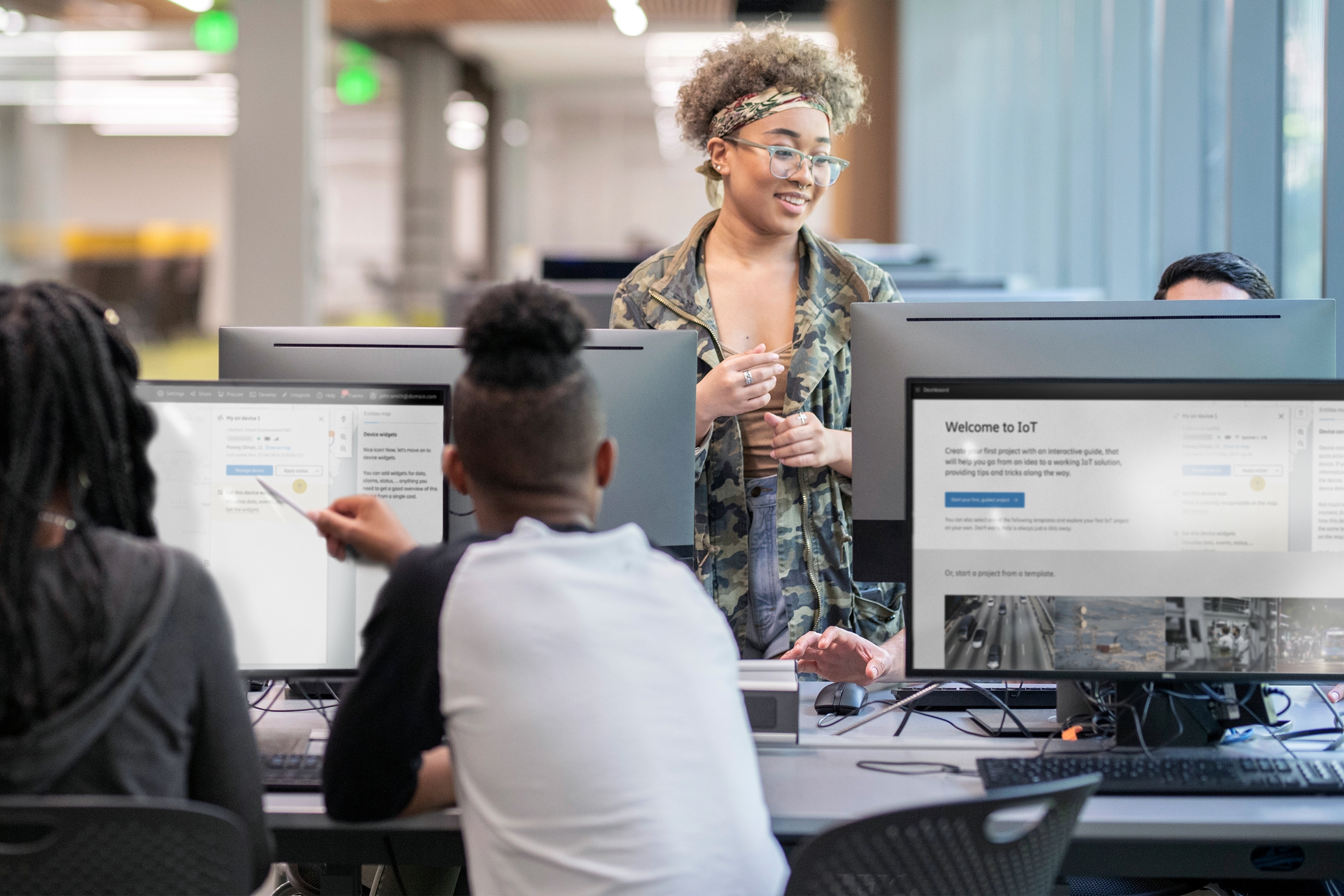

Including factory staff from the start

It all began with a kick-off workshop, where contributors from both companies met for the first time. There, we socialized as a product team, aligned on the challenges ahead and created shared knowledge. Kolektor’s factory staff were also willing to participate, joining us from their main manufacturing site in Slovenia. Their input helped confirm or deny the team’s assumptions on the spot, leading to a super productive session.

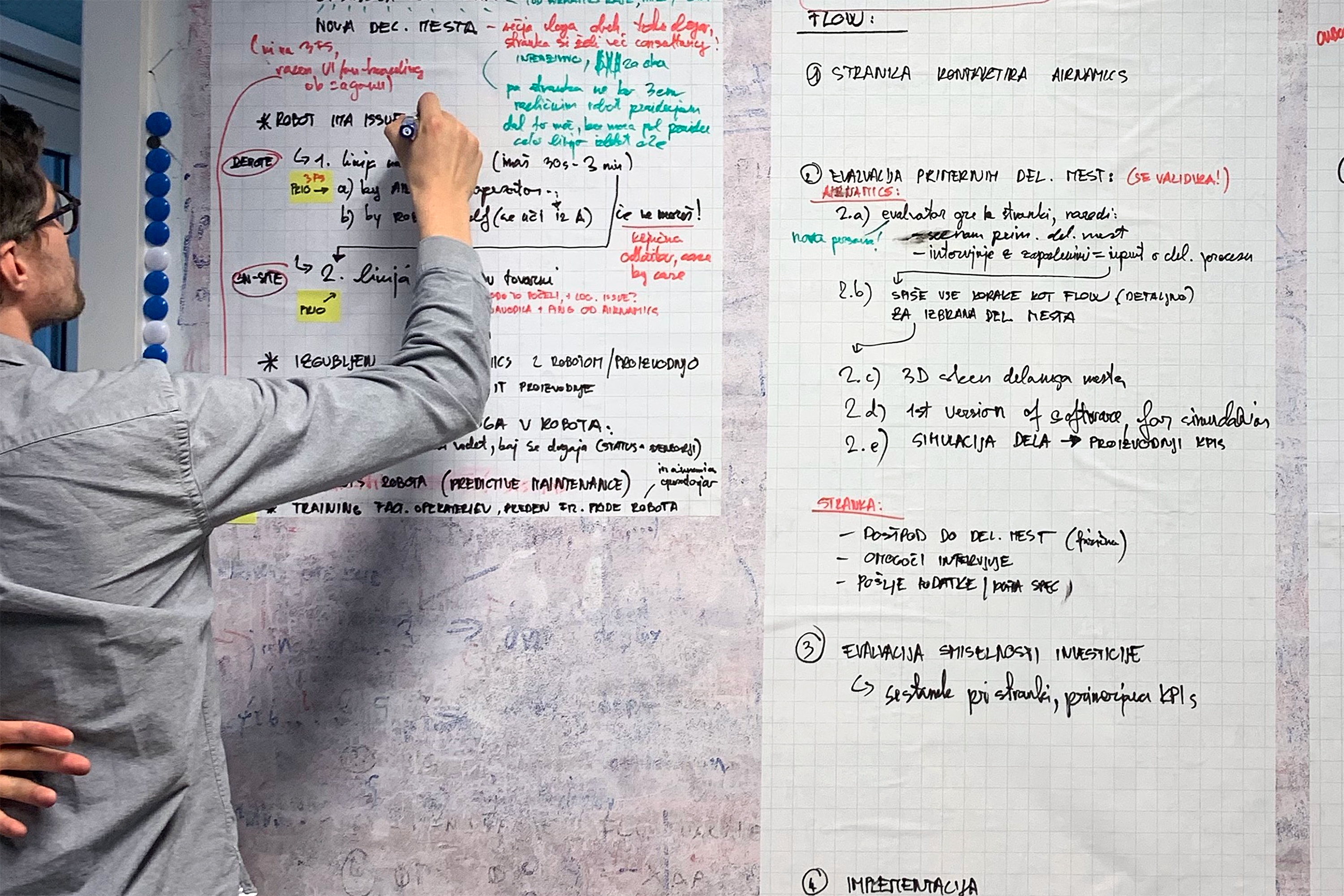

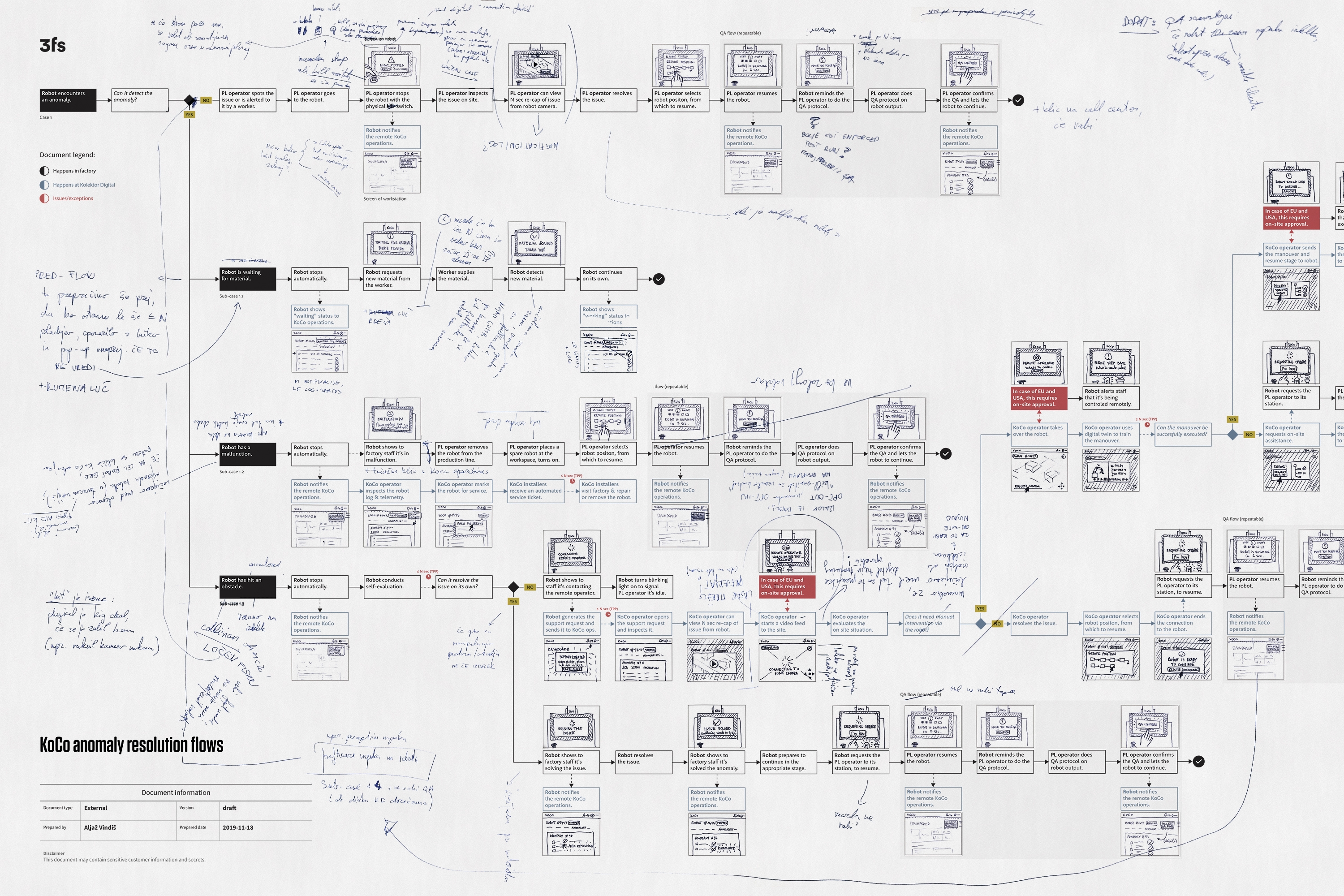

Map of a proposed new workflow, after a review session with Kolektor's factory staff.

First-hand experience in the factory

The kick-off led to a field trip, organized by our workshop guests. We familiarised ourselves with the production line in their facility, observed workers interacting with the R&D robot, and talked about their jobs. Designers detailed the use-cases and visualized the user flows. Engineers clarified technical details about the robot, its cameras, connectivity, and security. In the end, a rich conversation developed in-situ about a sensible scope and first deployment of the minimal viable product.

It took everyone just over two weeks to clarify and align on what was actually needed. This would have been impossible without the early access to the actual users and their working environment.

Quick wins

We also went through Kolektor Digital’s current R&D setup during these initial steps. Some improvements were needed to move from R&D mode into actual use, with global scalability in mind. We reviewed the existing source code, then implemented improvements to the software delivery pipeline, task management, documentation, and other DevOps best practices. We tested the changes on a relatively isolated and straightforward task: developing an API for automated retrieval of images and videos from the robot’s onboard cameras. All of this also facilitated a simpler and more productive collaboration going forward.

Pieces of the puzzle

Several distinct parts emerged as we hashed out the system architecture. First, we needed a core running in the cloud. As the central relay for all robot connections, it would also be saving the robot telemetry and visual data. Exposing it through an API would allow us to build web applications for remote operation or preventive maintenance with relative ease. Then there were the robots themselves, with their onboard operating system. This provided a software interface with the robot hardware but needed cloud connection capability and a custom onboard user interface to boot.

One of the crucial aspects in developing our solution has been the handover to robot deployment teams. 3fs set a benchmark with their practices and swift response time.

Working step-by-step, in parallel tracks

Confronted with a complex system like that, we prioritized our efforts to critical points, utilizing mock API interfaces and robot simulators. Thus, application development could proceed, while the cloud infrastructure and the robot’s internal systems were catching up. The decoupled approach enabled parts of the team to move at their own pace, like when the robots’ onboard application design slowed down due to complexities of advanced features, or when the robots’ operating system API had to be improved.

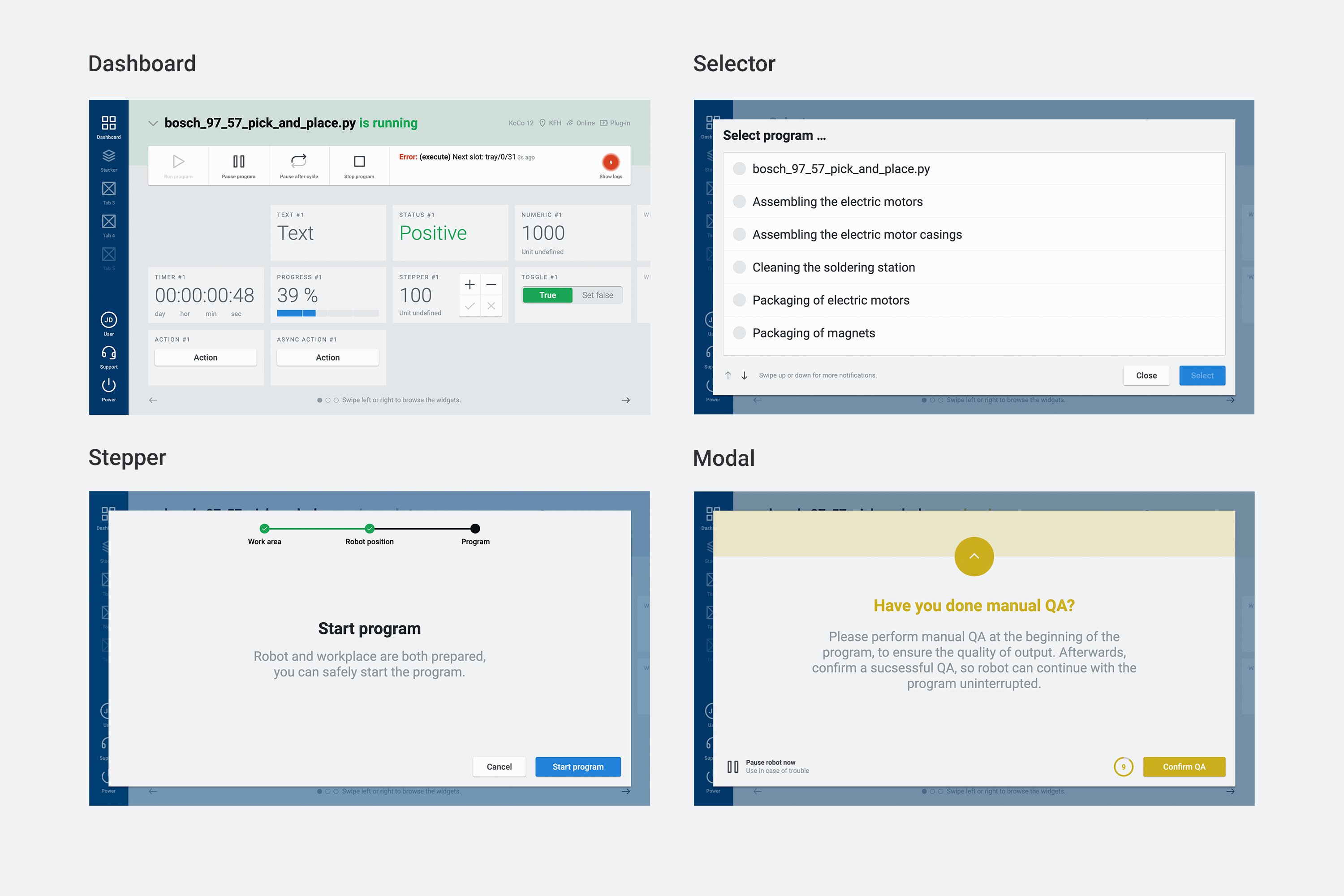

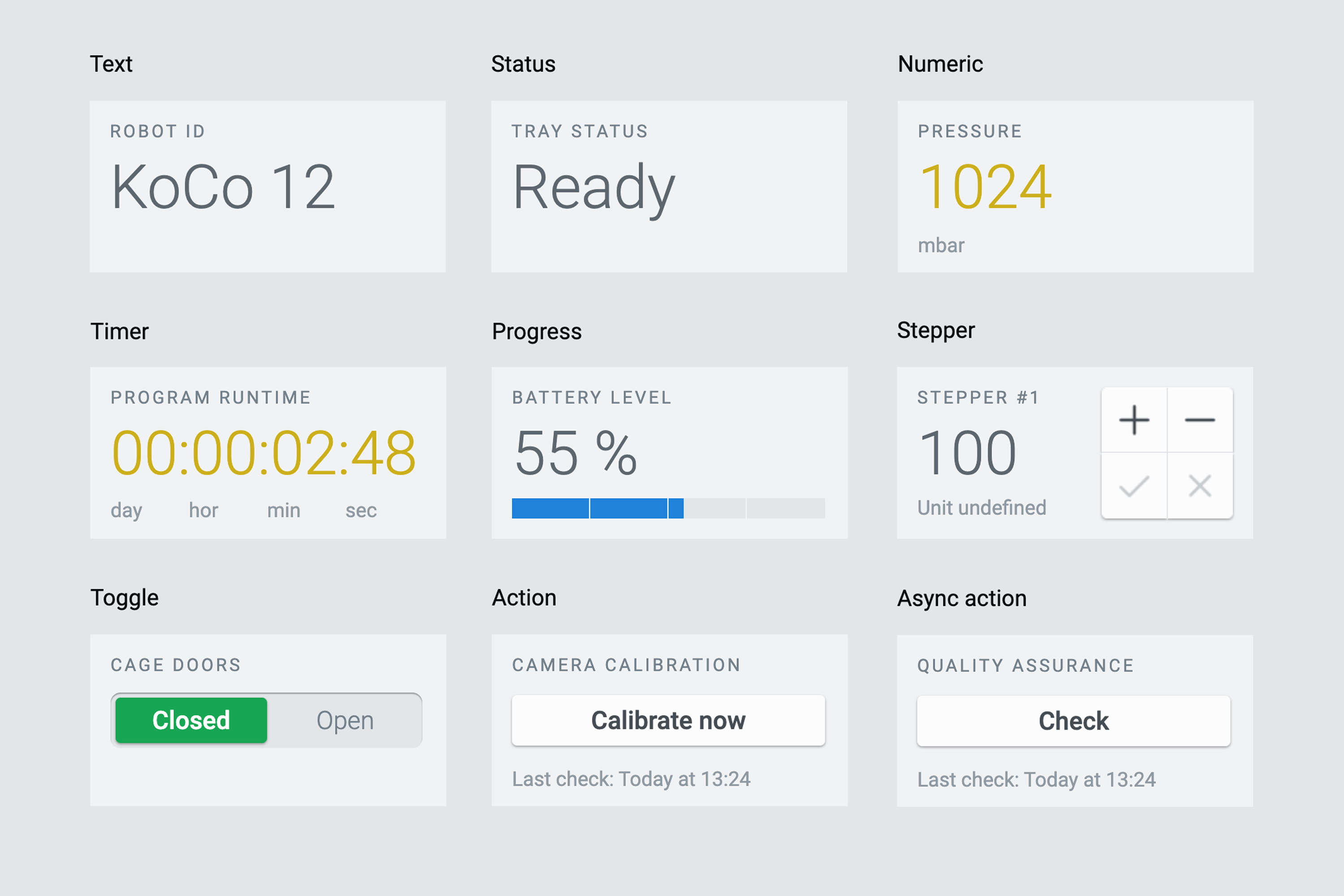

We used as little parts as possible for the interface, making use-case adjustments manageable for Kolektor's developers. Well established design patterns and micro-interactions aide with familiarity and accelerate adoption by factory workers.

The pivot

Kolektor Digital’s initial vision was to have a highly autonomous, cloud-connected fleet. As we progressed with development, it became clear that security constraints of the manufacturing environment make remote operations via digital twins s much less plausible scenario. In light of this, design emphasis was put on human-robot interaction in the factory. Engineers implemented the robots as edge nodes, with minimal dependency on the cloud. Remote access to robots would still be possible, but limited to diagnostics and support, and only if requested and approved on-site.

Prototyping for the win

Given the importance and complexity of human-robot interaction, we thoughtfully designed and thoroughly tested it. We used rapid prototyping methods: designers created highly realistic, interactive prototypes for each use-case, down to micro-interactions on the robot’s screen and the relevant state of auxiliary systems. Prototypes were informed by detailed discussions with engineers and prompted rich feedback from Kolektor Digital and factory staff. Because we were all working together, iterating towards the best possible solution before hand-off to production, we avoided costly changes that would otherwise occur later in the process.

We developed 9 different widget templates, that plug'n'play into the robot's OS and can be used in any arrangement.

To reduce human error and bad batches, QA protocols take form of helpful steppers. They further emphasise important actions with integration of robot's physical signals: lights and sounds. photo_camera by Kolektor Digital

From one-off to a reusable framework

Numerous possible robot hardware configurations, an endless array of different production line workflows, and various customer preferences were identified. When we got to the complex parts of the Robot UI – the robot programs and the operator dashboard with interactive widgets – it became clear we will have to build them in a modular fashion. This led to creation of a bespoke design system, and plug'n'play integration with the robots’ onboard API. More planning and upfront effort were justified by savings on configuration and support per each robot deployment. Kolektor's team has been operating the system succesfully, independently, ever since. close